INOXTORRES designs and manufactures CIP systems for the cleaning of preparation equipment, process and transfer lines for the pharmaceutical and cosmetic sectors.

Description of our Cips on-site cleaning systems

CIP Inox Torres cleaning systems are designed according to the cleaning needs of our customers, to ensure a complete cleaning of their equipment within their process plants.

Our teams are oriented to provide a complete, fully automated solution that facilitates start-up and qualification tasks. That is why our solutions are supplied in benches of easy installation, which integrate all the necessary components for the control of the cleaning process, as well as the system of control and automation of the same: tanks, systems of impulsion, dosage of cleaning agents , heat exchangers, etc. We also design and manufacture mobile and compact systems to bring cleaning to the equipment, without the need for a pipe installation.

The equipment is manufactured in high quality stainless steel, using orbital or TIG type welding methods. We can reach any internal finish that the client requires, from polished mirrors up to Ra <0.4μm to electropolished.

As for the qualification of the equipment, they are tested and validated according to strict quality protocols.

Our equipment integrates one or multiple tanks, from 100 to 5,000 liters, with the option of integrated electrical resistances.

Our Cips on-site cleaning systems offer numerous advantages

- 100% flexible design, depending on the needs of the end user

- High performance, optimizing energy and service consumption.

- Components of first brands.

- List of pre-filled recipes.

- Easy integration with the rest of the plant components.

- A high quality equipment, with GMP design, and complying with all the regulations in force (PED 2014/68 / CE, CE Marking, ASME BPE, etc …)

Safety in our on-site cleaning systems Cips

In cleaning, it is essential to adjust the parameters of pressure, temperature, duration of the cycle and composition of the cleaning solution. That’s why our systems adjust all these parameters in a precise way to guarantee a correct cleaning, validated and cyclical.

CIP systems can also control SIP sterilization, by feeding clean / pure steam from a generator set.

In this way, cleaning and sterilization are minimized by means of a single equipment, minimizing the installations and control systems.

Options and accessories

- Diaphragm valve.

- Flow control

- Recirculation with pump

- Conductivity control in drainage

- Communication with teams

- Software validation

- Dosing tanks

- Valves with limit switches

- Plate or tube exchanger

- Fixed or mobile bench

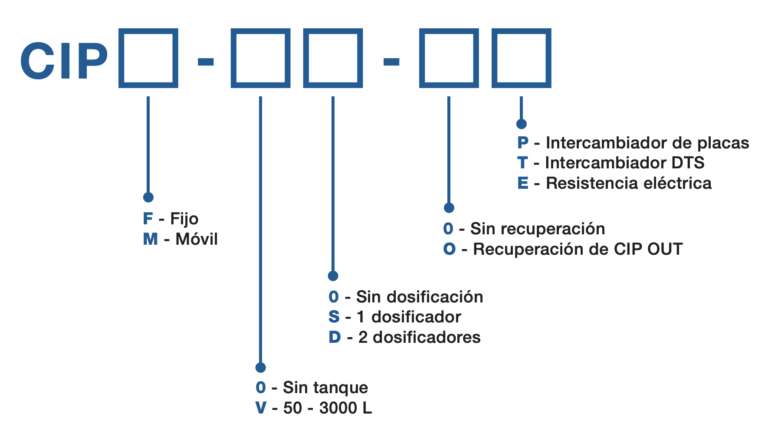

PRODUCT RANGE “RMGMP Models *”:

* The dimensions can be adapted to the needs of the user