Key principles of sustainable reactor manufacturing

Sustainable manufacturing in industrial reactor design focuses on minimizing the environmental impact while maintaining high levels of performance, safety, and efficiency. This means adopting processes that reduce energy consumption, waste production, and carbon emissions, all while using materials that are durable, non-toxic, and recyclable.

The transition towards sustainable reactor design involves integrating the principles of green chemistry and circular economy into the manufacturing process. These principles aim to reduce environmental impact throughout the reactor’s lifecycle, from raw material extraction to final disposal. Adopting sustainable practices enables compliance with regulations while supporting global climate goals by lowering carbon emissions and resource use.

Why sustainable manufacturing is important in reactor design

As industries worldwide move towards more sustainable practices, the design and manufacturing of industrial reactors must evolve to meet these demands. Industrial reactors play a critical role in many sectors, including energy, pharmaceuticals, chemicals, and petrochemicals. These sectors consume vast amounts of energy and materials, leading to significant environmental consequences.

Prioritizing sustainability in reactor manufacturing reduces ecological footprint and ensure their long-term viability. Sustainable reactors are more energy-efficient, cost-effective, and safer, benefiting both the environment and the bottom line. Moreover, adopting sustainable manufacturing practices aligns with growing regulatory pressure and societal expectations regarding environmental responsibility.

The environmental impact of traditional manufacturing processes

Common practices such as welding, machining, and casting can generate high levels of carbon emissions, while the extraction and processing of raw materials often deplete natural resources.

In addition, many conventional reactors are made from materials that are not easily recyclable or environmentally friendly. Traditional manufacturing methods can result in substantial waste, such as scrap metal, solvents, and other chemicals that must be carefully managed to avoid environmental contamination.

These draebacks have driven the adoption of more sustainable manufacturing techniques, which are designed to minimize resource usage, energy consumption, and waste generation, all while enhancing the performance and safety of the reactors.

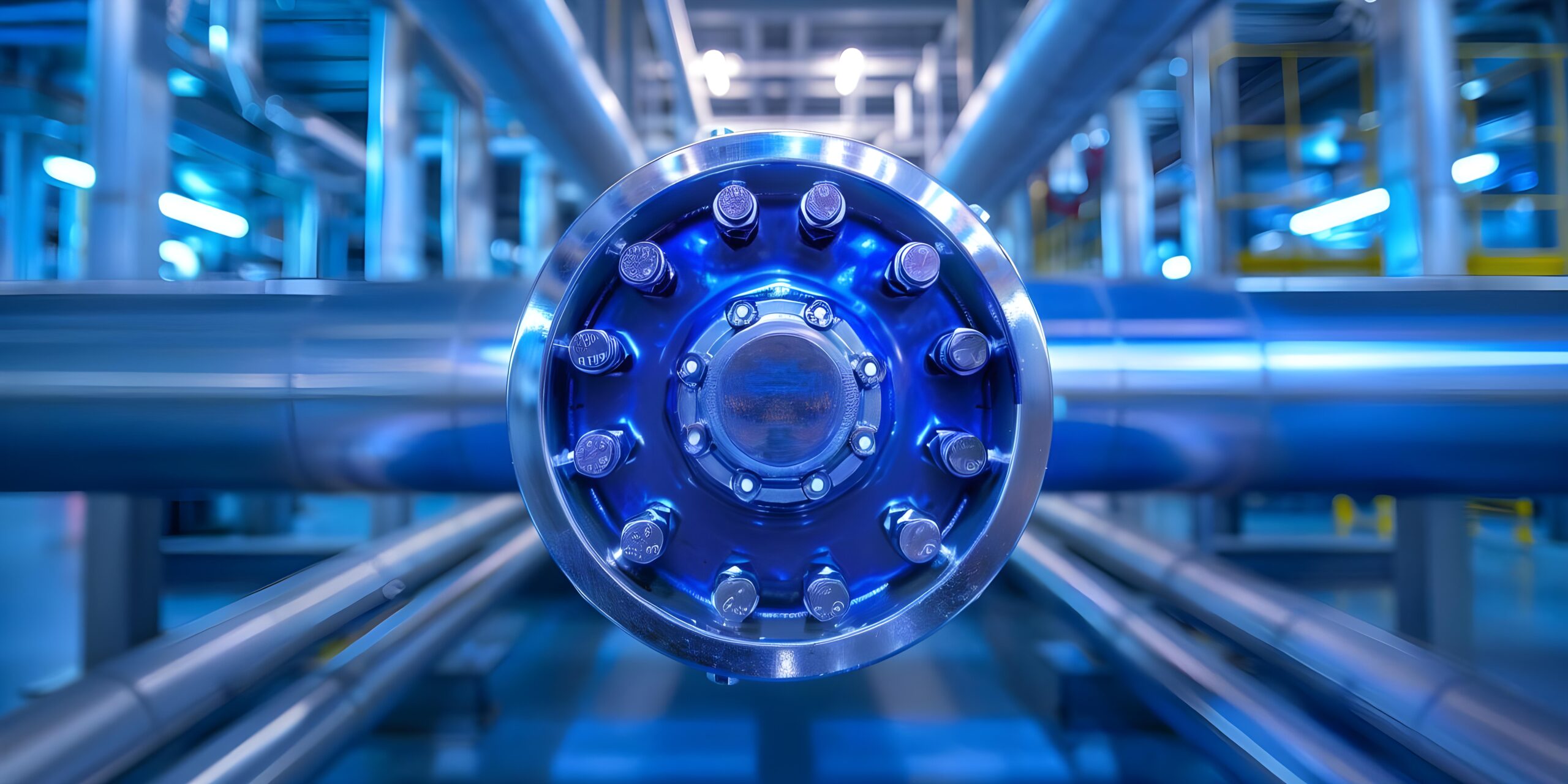

Sustainable manufacturing methods for industrial reactors

As the demand for sustainable practices increases, various manufacturing methods have been developed to make industrial reactors more environmentally friendly. These methods focus on improving energy efficiency, reducing waste, and using eco-friendly materials in the design and production of reactors.

Energy-efficient manufacturing processes for industrial reactors

Energy efficiency is one of the key aspects of sustainable reactor design. Optimizing energy use lowers both operating costs and environmental impact. Techniques such as energy recovery, heat integration, and the use of renewable energy sources can significantly reduce the amount of energy needed during reactor production.

- Energy-efficient welding techniques: Advanced welding technologies, such as laser welding and orbital welding, can minimize energy consumption by reducing the heat required for the process.

- Utilizing waste heat: Implementing systems that capture and reuse waste heat from the manufacturing process can reduce the need for external energy sources.

By integrating these energy-efficient practices, manufacturers can reduce the carbon footprint of reactor production while maintaining high levels of performance and durability.

Minimizing waste and reducing environmental impact

Another essential aspect of sustainable reactor manufacturing is minimizing waste generation. Traditional manufacturing often involves the production of excess materials, scrap metal, and harmful by-products, all of which must be disposed of properly. Sustainable manufacturing methods aim to reduce waste at every stage of the production process.

- Material efficiency: Using precision fabrication techniques and optimizing designs to minimize material waste is a fundamental approach. For example, laser cutting and 3D printing can help create more precise parts with less material waste.

- Recycling and reusing materials: Recycling scrap materials, especially metals like stainless steel and titanium, reduces the need for raw material extraction and minimizes the environmental impact of manufacturing.

- Reducing hazardous by-products: Sustainable reactors can be designed to minimize the creation of harmful substances during operation. For instance, green chemistry principles are incorporated into the reactor design to limit the use of toxic chemicals.

Benefits of sustainable reactor design

Sustainable reactor design offers numerous benefits beyond environmental gains. It also contributes to increased efficiency, reduced costs, and improved safety across the entire manufacturing and operational lifecycle of reactors. The adoption of sustainable practices in reactor design offers advantages for manufacturers, operators, and the environment alike.

- Reduced environmental impact: Sustainable reactors are designed to minimize waste, reduce emissions, and lower energy consumption, leading to a smaller ecological footprint.

- Enhanced safety: By using non-toxic materials and safer manufacturing processes, sustainable reactor designs improve worker safety and reduce the likelihood of accidents or hazardous exposure.

- Increased market competitiveness: As the demand for sustainable products increases, manufacturers that prioritize sustainability gain a competitive edge in the market, appealing to both regulatory bodies and environmentally conscious consumers.

- Longer operational life: Sustainable reactors are built with durability in mind, meaning they last longer and require less maintenance, ultimately reducing downtime and operational disruptions.

Best practices for sustainable manufacturing in reactor production

Ensuring sustainability in reactor manufacturing requires a strategic approach that incorporates the latest technologies, processes, and materials. Below are some best practices that have proven effective in reducing environmental impact while enhancing reactor performance.

Optimizing production processes to minimize environmental footprint

- Adopt energy-efficient technologies: Implementing energy-saving equipment and processes such as low-energy welding, material-saving fabrication, and heat recovery systems is essential to reducing energy consumption in reactor production.

- Choose sustainable materials: Selecting materials that are both durable and environmentally friendly, such as recyclable metals or low-impact coatings, ensures that the reactor remains eco-friendly throughout its life cycle.

- Implement waste reduction measures: By incorporating lean manufacturing principles, it’s possible to minimize waste generation, maximize material efficiency, and reduce the need for raw materials.

- Incorporate green chemistry: Where possible, incorporate green chemistry practices to reduce the environmental impact of the chemical reactions taking place in the reactor.

By adopting these sustainable practices, manufacturers can significantly reduce their environmental footprint while maintaining high standards of quality and efficiency.