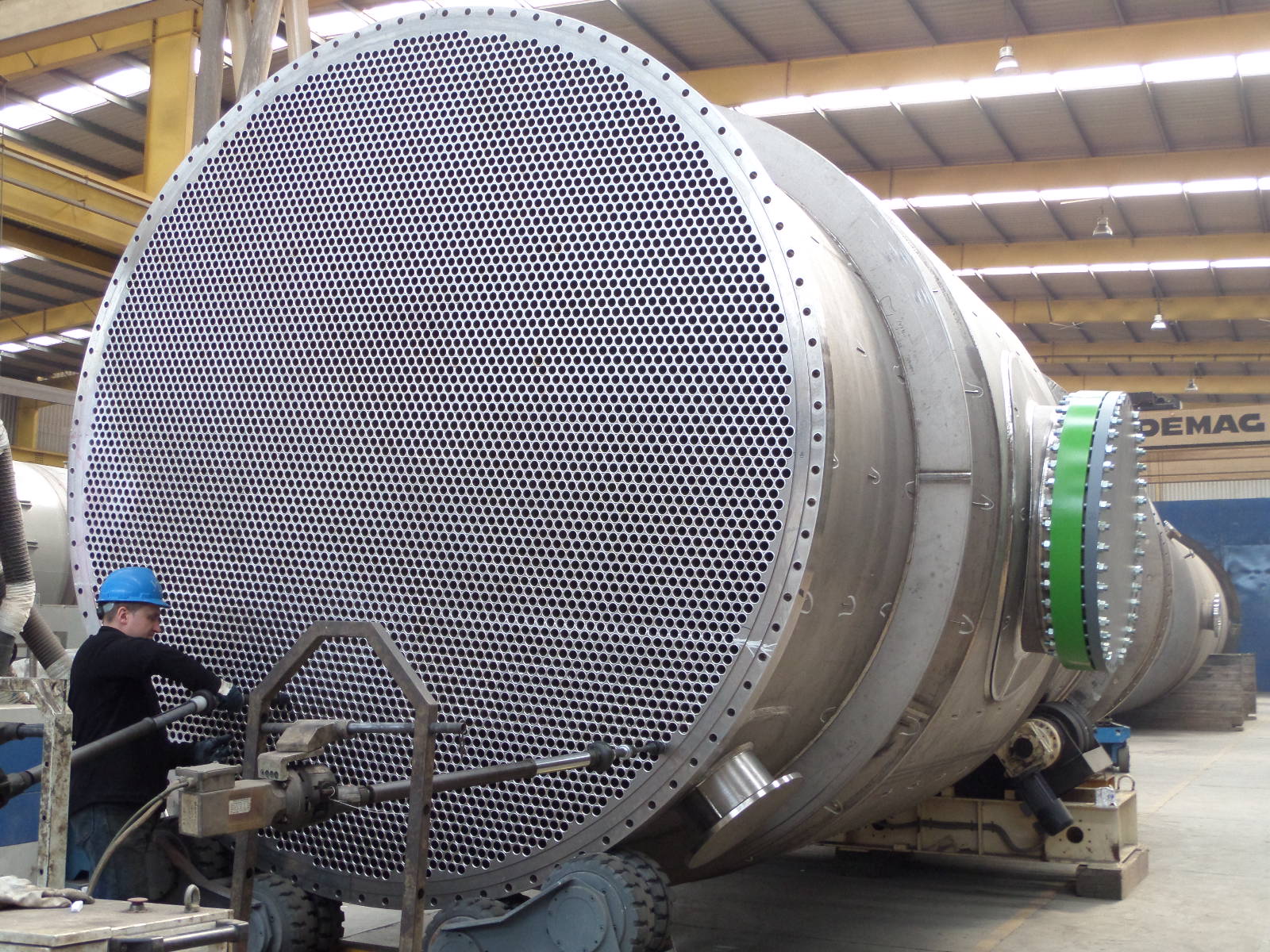

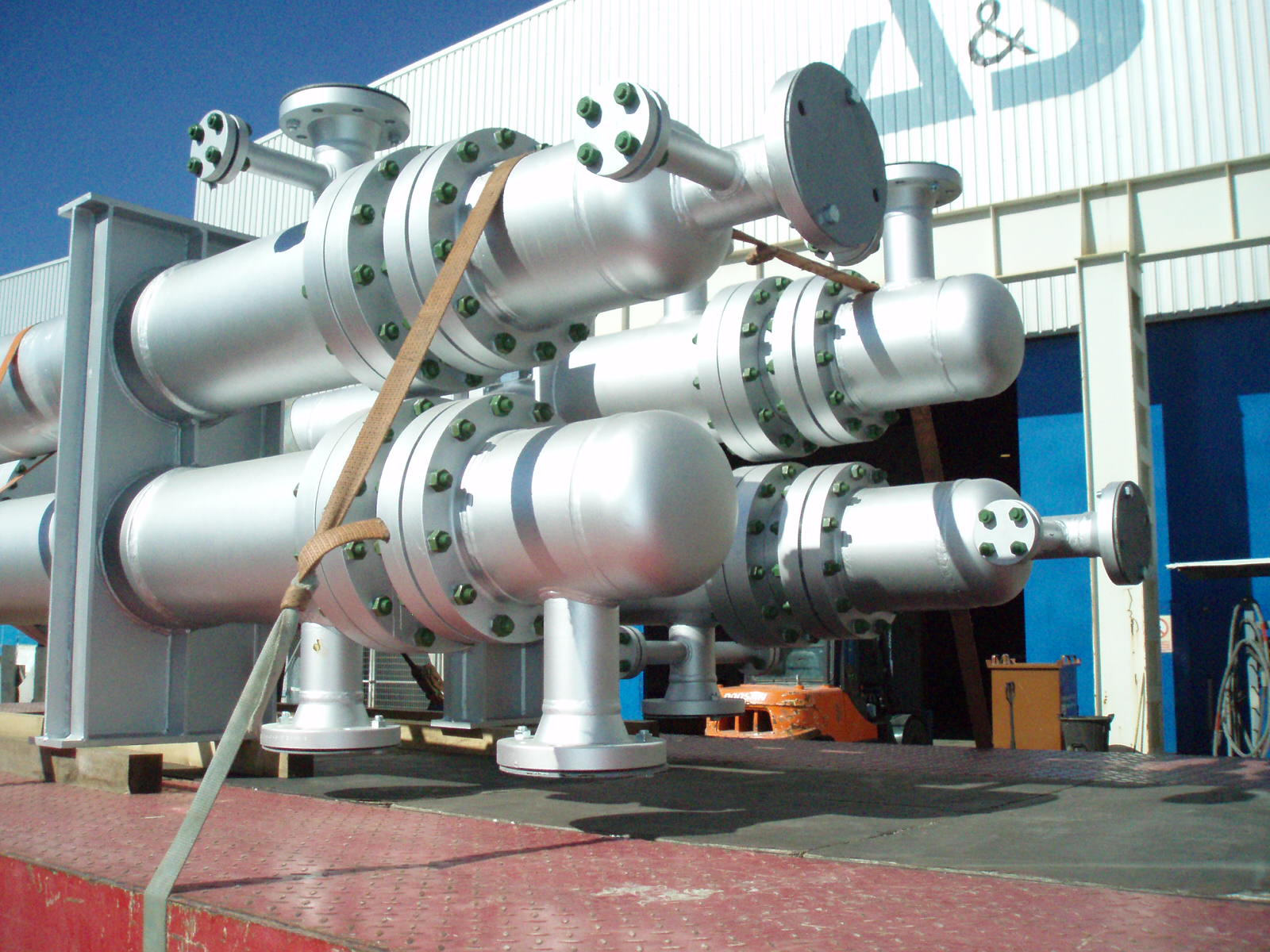

Shell & Tube Heat Exchangers

For decades, we have been leaders in shell and tube heat exchangers, delivering durable and high-performance solutions. Our exchanger designs maximize efficiency and reliability, ensuring superior thermal performance and endurance. With advanced engineering and cutting-edge software, we refine heat exchangers to meet the most demanding industrial needs.

Main features of our heat exchangers

- We design and manufacture shell and tube heat exchangers using Stainless Steel, high nickel alloys, duplex, superduplex and Titanium.

- Our solutions are fully customized based on process parameters, industry requirements ensuring an optimized heat transfer coefficient.

- We produce units ranging from small-scale systems to tube bundles weighing up to 300 tons.

- Our exchangers are suitable for both low and high-pressure applications, including single-pass and multi-pass configurations.

- All equipment complies with ASME, EU norms (EN13445), TEMA, AD, China & Korean Standards and more, guaranteeing high-quality performance.

INDUSTRIAL APLICATIONS

Shell and tube heat exchangers are widely used across various industries due to their ability to transfer heat efficiently while handling high-pressure environments, high temperatures, and corrosive materials. Common industrial applications include:

- Petrochemical Industry: used for heat recovery, cooling processes, and temperature control in refining and chemical production.

- Oil & Gas: essential in condensers, reboilers, and heat recovery systems for upstream and downstream operations.

- Power Generation: employed in steam generators, cooling systems, and heat recovery units to maximize energy efficiency

- Chemical Processing: used in reactors, crystallizers, and evaporators to manage temperature in complex chemical reactions.

Our shell and tube heat exchangers are customizable to meet the unique needs of each application, providing optimized heat transfer solutions for demanding industrial environments.

High-performance shell and tube heat exchangers

At InoxTorres Group, we specialize in shell and tube heat exchangers designed for high efficiency and durability. Using high entropy alloys and precision engineering, we optimize heat transfer area, fluid flow, and mechanical resistance.

- We master tube-to-tubesheet joints through light or heavy expansion, seal welding, strength welding, and hybrid techniques, ensuring perfect bonding between the shell and tubes for durability and performance.

- Optimized flow and heat transfer – As expert manufacturers of shell and tube heat exchangers, we enhance flow rate, thermal efficiency, and pressure resistance for demanding applications.

- Custom solutions for every industry from high-pressure systems to exotic materials, we design tailored solutions that meet the strictest industrial standards.

Let us guide you through the best alternative according to your application and requirements.

FAQ

What materials are used in the construction of Shell and Tube Heat Exchangers?

We design and manufacture shell and tube heat exchangers using a wide range of materials, including stainless steel, high nickel alloys, duplex, super duplex, and titanium, among other exotic materials. These materials are selected based on the specific application requirements, ensuring optimal performance and longevity.

How do you ensure the quality and reliability of the heat exchangers?

At Inox Torres Group, we ensure the highest quality and reliability through precision engineering, advanced manufacturing techniques, and rigorous testing. Our heat exchangers undergo comprehensive quality control processes, including material inspection, welding tests, and performance evaluations, to meet the strictest industrial standards.

What certifications do your Shell and Tube Heat Exchangers hold?

Our shell and tube heat exchangers are manufactured in accordance with strict international standards and hold certifications such as ASME, PED, and ISO 9001. These certifications ensure that our products meet the highest quality, safety, and performance standards required for industrial applications.

Do your heat exchangers meet environmental and sustainability standards?

Our heat exchangers are designed and manufactured in compliance with current environmental and sustainability standards. We prioritize energy efficiency, material optimization, and long service life to reduce environmental impact. Our manufacturing processes follow international norms and best practices to minimize waste, emissions, and resource consumption, ensuring sustainable performance throughout the equipment’s lifecycle.