Reactors

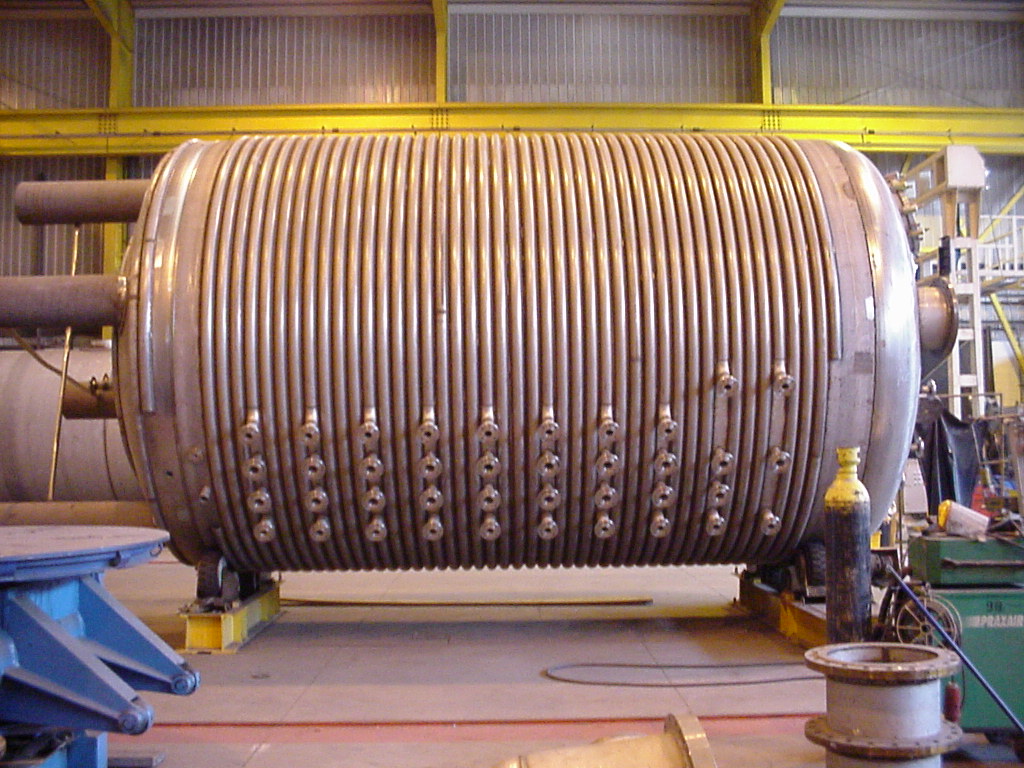

We specialize in the design and manufacturing of high-quality reactors, engineered for a wide range of chemical processes. Our reactors are designed to meet the most demanding operational conditions, ensuring reliability, safety, and optimal performance. Whether for batch or continuous processes, we provide tailored solutions that guarantee long-lasting results in the most precise and robust manner.

Main features of our Reactors

- Suitable for both low and high-pressure applications, ensuring adaptability to various operational environments.

- We manufacture reactors using a variety of materials, including stainless steel, high nickel alloys, duplex, superduplex, cladding, and titanium.

- Insulation options for heat retention and compliance with ATEX standards for safety in explosive environments.

- Reactors can be equipped with cooling or heating systems, including jackets, half coils, internal coils, dimple jackets, and electrical tracing, for precise temperature regulation.

- Available with or without agitation systems, designed to enhance reaction efficiency and optimize mixing.

INDUSTRIAL APLICATIONS

Reactors are essential for facilitating a variety of complex chemical reactions under precisely controlled conditions. Typical applications include distillation, polymerization, oxidation, and crystallization, where precise control over temperature, pressure, and reaction time is vital for achieving optimal results.

- Petrochemical Industry: used for polymerization, pyrolysis, and distillation reactions, essential for the production of petrochemical derivatives.

- Pharmaceuticals: employed in batch reactors for drug synthesis, ensuring precise control over temperature and reaction time.

- Chemical Processing: used in various chemical reactions such as oxidation, crystallization, and polymerization.

- Fine Chemicals: applied in continuous processes for fine chemical production, where high precision and control are required.

From batch reactors to continuous processes, our reactors provide flexible solutions for diverse chemical reactions, ensuring efficiency, precision, and safety.

Innovative Reactor solutions for high-efficiency processes

At InoxTorres Group, we prioritize delivering reactors that not only meet but exceed industry expectations. Our reactors are designed for maximum efficiency, ensuring consistent performance even under the most challenging conditions. The ability to tailor each reactor to specific chemical processes means our clients benefit from optimized energy use, reduced operational costs, and enhanced productivity. With advanced manufacturing techniques, we provide solutions that ensure long-term durability, minimal downtime, and seamless integration into complex industrial setups.

Energy Optimization: custom designs that ensure efficient energy use, reducing operational costs and improving overall productivity.

Enhanced Durability: robust reactors built to withstand the toughest industrial environments, minimizing maintenance and downtime.

Tailored Solutions: reactors customized to meet specific process requirements, ensuring seamless integration and optimal performance.

FAQ

What types of chemical reactions can your reactors handle?

Our reactors are designed to handle a wide variety of chemical reactions, including polymerization, oxidation, distillation, crystallization, and extraction. Whether for batch or continuous processes, we provide reactors tailored to meet specific chemical and operational requirements.

What is the maximum pressure your reactors can handle?

We manufacture reactors to handle both low and high-pressure applications, with custom designs available to meet specific process conditions. The maximum pressure depends on the reactor’s design, materials used, and the requirements of the chemical process.

What materials are your reactors made from?

We design and manufacture reactors using a range of materials, including stainless steel, high nickel alloys, duplex, superduplex, titanium, and other specialized materials. The choice of material depends on the specific chemical process, temperature, pressure, and corrosion resistance required.

What size reactors do you manufacture?

We manufacture reactors in a wide range of sizes, from small-scale systems to large units weighing up to 300 tons. Our reactors can be custom-designed to meet specific requirements, with diameters up to 8 meters and lengths up to 50 meters, ensuring a perfect fit for any application.