Equipment portfolio

Our portfolio of special alloys stainless steel and titanium equipment is designed to meet and exceed the highest industry standards, ensuring quality and expertise.

(01)

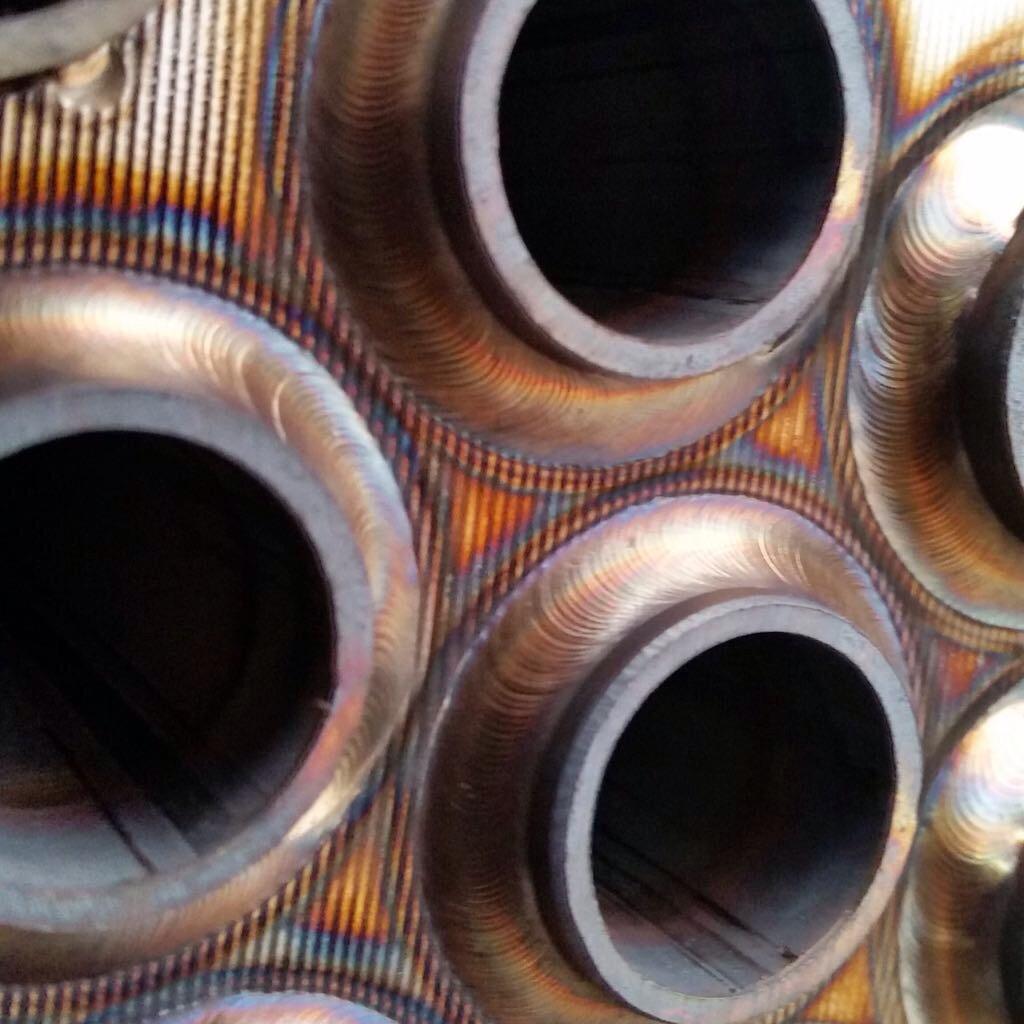

SHELL & TUBE

HEAT EXCHANGERS

We specialize in high-performance shell and tube heat exchangers, designed to optimize thermal efficiency in industrial applications. Engineered for durability and reliability, our solutions ensure optimal heat transfer while maintaining superior resistance to pressure and corrosion.

- Both low and high pressure equipment

- Shell & Tube Heat Exchanger

- High nickel alloys

- Orbital and robot welding

- Titanium

- ASME, EU norms (EN13445) TEMA,

Pressure Vessels

Our stainless steel pressure vessels are designed for durability, safety, and optimal performance in demanding industries. Engineered for extreme pressures, they ensure reliability, efficiency, and compliance with global standards, making them the ideal solution for critical applications.

- Stainless steel & exotic alloys

- High & low-pressure designs

- Vertical & horizontal configurations

- Certified welding & FEA analysis

- Heating & cooling jackets

- Compliance with ASME & EN13445

(03)

COLUMNS

& TOWERS

Our industrial columns and towers are designed for efficiency, durability, and safety in complex chemical and mechanical processes. Engineered to withstand high pressures, vacuum conditions, and extreme environments, they ensure optimal performance while meeting global industry standards.

- Custom-built for specific industrial processes

- Large-scale units up to 300 tons

- Seismic & wind-resistant structural design

- Skirt or bracket support options

- Optimized weight

- Rigorous quality control

(04)

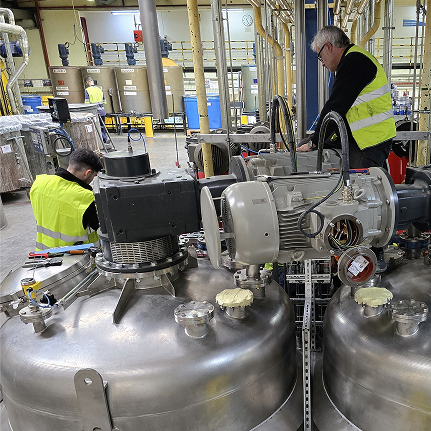

REACTORS

Our Industrial reactors play a crucial role in chemical processing, enabling precise control over temperature, pressure, and reaction conditions. The reactors combine high-quality materials with advanced engineering to maximize efficiency, safety, and long-term reliability.

- Configurations with or without agitation

- Heating & cooling

- Polished & electro-polished finishes

- Insulation & electrical tracing options

- ATEX-certified for hazardous environments

(05)

INDUSTRIAL INSTALATIONS

We specialize in the design, planning, manufacturing, and validation of industrial installations for highly regulated sectors such as pharmaceutical, cosmetic, food, and chemical industries. Our expertise enables us to deliver customized solutions that meet the highest standards of quality, hygiene, and safety.

- Customized installations for regulated industries

- Advanced engineering services: 3D design, P&ID, isometrics

- Certified compliance with ASME, GMP, ATEX standards

- Certified welding procedures and extensive testing

- Strict adherence to DQ/IQ/OQ/PQ protocols and FAT/SAT”

(06)

After-sales Service

“We provide comprehensive after-sales service designed to ensure that your industrial installations operate optimally, safely, and in full compliance with the highest standards for each industry. Our dedicated technical support maximizes the lifespan and performance of every installation, helping you achieve continued success.

- Technical support during start-up and production cycles

- Preventive maintenance for critical components

- Quick corrective maintenance interventions

- Original spare parts with full traceability

- Retrofit services for energy efficiency and updates”