Manufacturing Capabilities: Innovation, Precision, and Quality

At Inoxtorres, we pride ourselves on our state-of-the-art capabilities and extensive expertise in manufacturing high-quality industrial equipment. From robust infrastructures to advanced design codes, precision welding, and custom solutions, we deliver top-tier products that meet the most demanding industry standards.

Production Sites

Barcelona: modern design for a pressure vessel workshop

Les Franqueses Workshop

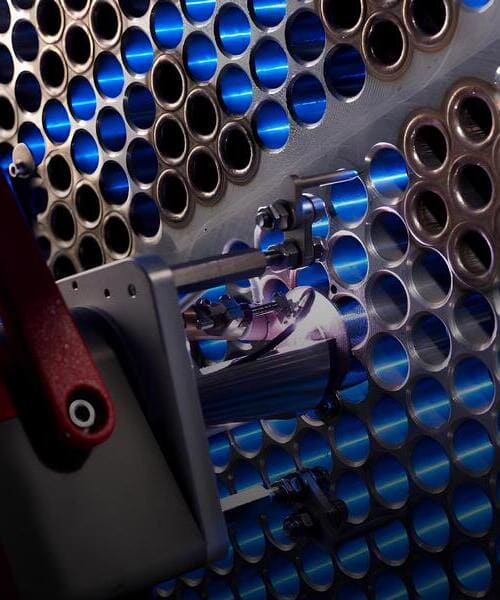

Located in Barcelona, our workshop is dedicated to manufacturing Shell and Tube Heat Exchangers and Pressure Vessels. Designed for efficiency and safety, it features:

- 24,000 m² of space

3 under-roof halls for production, including a dedicated hall for Titanium and exotic alloys - 5 m diameter, 40 m long equipment capabilities

- Fully craned for easy material handling

- Bunker for pneumatic testing and radiographic inspection (Rx)

Tarragona: portside large-scale equipment manufacturing

Tarragona Port Workshop

Our Tarragona workshop is specialized in large dimension equipment manufacturing, strategically located within Tarragona Port to reduce inland transportation costs. Key features include:

- 48,000 m² of space

- Designed for large dimension equipment with up to 8 m diameter, 50 m long

- Fully craned under-roof halls

- Wide yard for manufacturing and storage

International Standards for Industrial Equipment Design

Our equipment is designed and manufactured in accordance with the most recognized international codes and standards, guaranteeing consistent quality and performance:

ASME

EN-13445 (European Code)

AD-2000

CODAP

We are fully authorized to export worldwide, including regions such as USA, Canada, China, Australia, Korea, Malaysia, Argelia, etc, ensuring we meet global industry standards across borders.

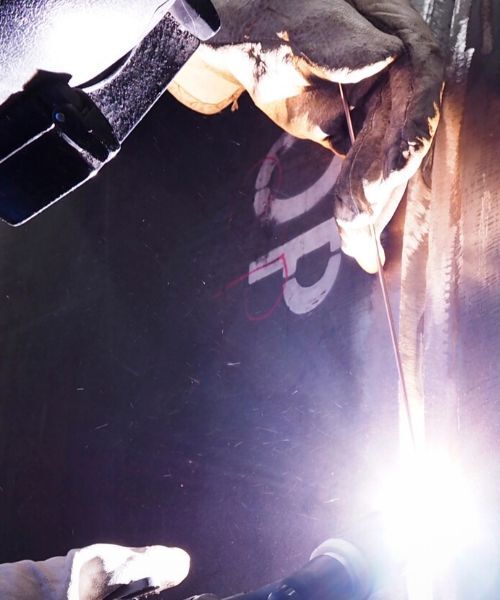

Welding is at the heart of our pressure vessel manufacturing process. We combine advanced welding techniques with rigorous quality control to ensure the highest strength, durability, and safety for every piece of equipment.

(01)

Certified Welding Procedures:

Adhering to ASME, EN, AD, and other international standards for precision and compliance.

(02)

Advanced Welding Techniques:

Our expertise includes GTAW (TIG), GMAW (MIG/MAG), SAW (Submerged Arc Welding), and SMAW (Stick Welding).

(03)

High-Quality Materials:

We specialize in welding stainless steel, high nickel alloys, duplex, superduplex, and titanium.

(04)

Non-Destructive Testing (NDT):

Every weld undergoes X-ray, ultrasonic, and dye penetrant testing to ensure integrity and safety.

(05)

Experienced Welders:

Our certified team of welders ensures precision in every weld, guaranteeing the strength and safety of your installations.

With nearly 80 years of experience, at InoxTorres we combine expertise, technology, and innovation to manufacture world-class industrial equipment. Whether it’s large-scale installations, precision welding, or custom solutions, we ensure that every product meets the most demanding industry standards and provides long-term value.